If you’re running tests in Tricentis Tosca and managing quality in Xray for Jira, you already know the struggle: keeping results in sync and maintaining traceability. Without a smooth connection, test cases get duplicated, reporting breaks apart, and teams lose valuable hours every week. At Automators AI, the good news is Tosca and Xray can work together.

In this guide, we’ll show you how to integrate them using the most reliable approach: our Tosca–Xray Connector, a purpose-built middleware that handles these API calls for you. We’ll also briefly mention the other approaches, such as writing your own REST API scripts or using generic middleware platforms.

5 Steps to Connect Tosca and Xray using our Tosca Xray Connector

Getting Tosca and Xray to work together shouldn’t feel like an IT project on its own. With our connector, the setup is straightforward. Here’s how it works:

Step 1. Get Access to the Connector

Reach out to our team to obtain the Tosca–Xray Connector package and licensing details. Since this isn’t a public “download-and-install” tool, setup starts with our support team ensuring you have the right version for your Tosca and Jira/Xray environment.

Step 2. Configure Authentication

Update the connector with your Jira project details and Xray API credentials. Once authenticated, Tosca and Xray begin exchanging data automatically through REST API calls.

Step 3. Sync Test Cases

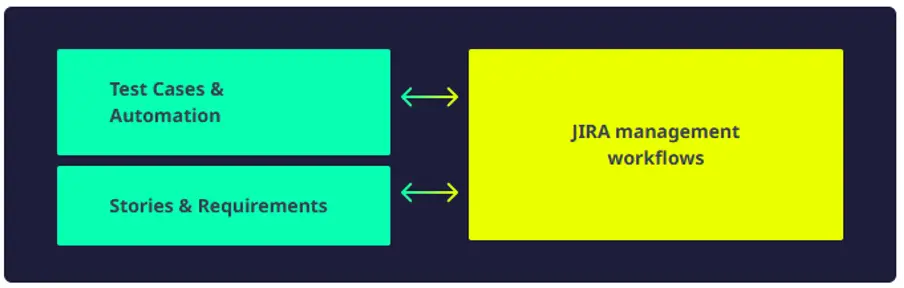

Tosca test cases can be pushed directly into Xray, and Jira requirements managed in Xray can flow back into Tosca for execution. This two-way sync keeps both systems aligned, no matter where tests are designed.

Step 4. Sync Execution Results

When Tosca executes a test, the connector sends the full results to Xray automatically:

- Pass/fail status

- Step-level details

- Execution logs and metrics

- Screenshots for failures

This ensures Jira becomes the single source of truth, now managers no longer need access to Tosca just to understand what happened.

Step 5. Validate in Xray Dashboards

Once results are synchronized, QA leads and business stakeholders can track live reports directly in Jira. End-to-end traceability, from requirements to test cases, executions, and defects, is visible in a single place.

Behind the scenes, the connector also translates Tosca’s model-based tests into Xray’s step-based structure. Here’s how that mapping works:

Artifact Mapping at a Glance

To make it clearer how the sync works, here’s how Tosca artifacts align with Xray:

| Tosca Artifact | Xray Artifact | Direction | Purpose |

|---|---|---|---|

| Test Case (Automated/Manual) | Xray Test Issue | Bi-directional | Unified definition and coverage tracking |

| Test Case Variants / Attributes | Xray Test Steps | Tosca → Xray | Translate logical Tosca models into actionable steps |

| Execution List / Execution Entry | Xray Test Execution Issue | Tosca → Xray | Aggregate results of automated runs |

| Logs, Screenshots, Evidence | Xray Test Run Attachments | Tosca → Xray | Full traceability, compliance, and defect triage |

This mapping is what makes the connector different from a basic data pipe. It doesn’t just dump results; it translates Tosca’s model-based tests into the step-based structure that Xray understands, ensuring reports stay meaningful.

Here’s why it matters in real life:

Why This Artifact Mapping Matters for QA Teams

It’s not enough to just move data from Tosca into Jira. The real challenge for QA teams lies in two areas:

1. Tool Sprawl

Most enterprises use best-of-breed tools: Tosca for automation, Xray for test management, Jira for requirements, and so on. Each tool excels on its own, but when they operate in silos, testing slows down. Managers can’t see the full picture, business users can’t access automation results, and testers waste time duplicating work.

2. The Translation Gap

Tosca and Xray speak different “languages.” Tosca is model-based: you design reusable modules and logical test cases. Xray is step-based: it tracks execution step by step with expected results. Without a proper translation layer, automated runs from Tosca don’t translate cleanly into the step-driven reports Xray needs for requirement coverage.

This is why a simple script or generic middleware isn’t enough. To truly achieve end-to-end test management, you need a connector that not only syncs data but also translates it into meaningful artifacts. That’s what turns Tosca automation into actionable Xray reports.

Of course, there are other ways to connect Tosca and Xray, and it’s worth understanding them before we compare approaches.

Other Options (and Why Teams Look Beyond Them)

a. DIY with REST APIs

Xray provides REST endpoints to import execution results. In theory, you can export Tosca results, convert them into JSON, and push them into Xray. In practice, this means writing and maintaining custom scripts, and every Tosca or Xray update risks breaking them. It works, but it requires ongoing engineering effort.

b. Generic Integration Platforms

Tools like Planview or OpsHub can also synchronize data between Tosca and Xray. These platforms are useful if you need to connect many systems across your toolchain. But because they aren’t built specifically for Tosca ↔ Xray, they don’t handle artifact translation or detailed evidence as well.

That’s why many teams move to a dedicated connector built specifically for Tosca and Xray.

Here’s what sets our Tosca Jira Xray integrator apart:

Why Teams Choose Automators AI’s Tosca–Xray Connector

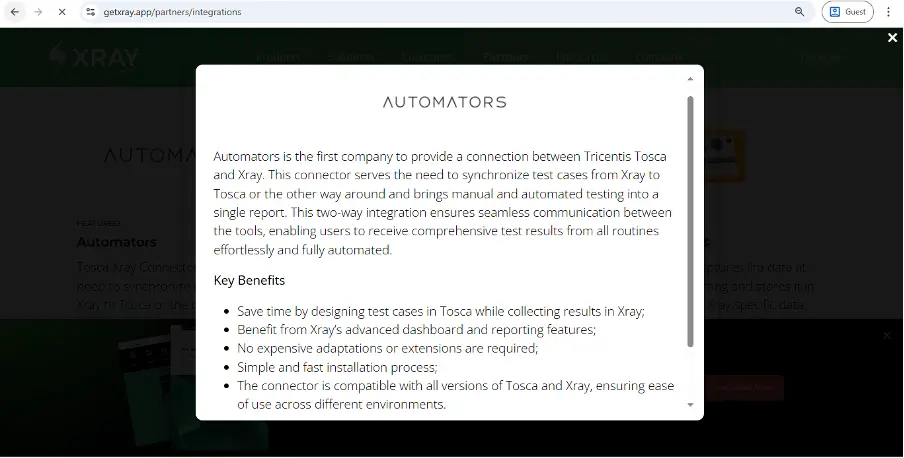

1. Recognized and Trusted

We were the first to provide a dedicated Tosca–Xray connector, and we’re listed directly on the Xray integrations directory. As a Tricentis partner, our solution is aligned with Tosca’s roadmap and enterprise standards.

2. Bi-Directional Synchronization

Test cases flow both ways: Tosca test definitions can be pushed into Xray, and Jira requirements managed in Xray can be pulled into Tosca for execution.

This keeps automation engineers and business stakeholders working in the tools they know best, without duplication.

3. Full Results and Evidence

Every execution in Tosca is instantly reflected in Xray, complete with pass/fail status, step-level details, logs, and screenshots. Managers no longer need Tosca access to see what happened; all the context lives in Jira.

4. AI-Powered Error Analysis

Beyond moving data, the connector includes AI-based error classification. It automatically separates genuine business defects from temporary technical noise, cutting error analysis time by up to 90% in high-volume environments. That means QA engineers spend less time chasing flaky runs and more time improving test design.

5. Compatibility and Stability

The connector is tested against all versions of Tosca and Xray, so teams don’t have to rewrite scripts every time a tool updates. Installation is simple, with no expensive custom adaptations required.

6. Lower Total Cost of Ownership

Because it’s purpose-built and maintained by us, the connector reduces the long-term cost of integration. Enterprises no longer absorb the hidden expense of maintaining fragile scripts or relying on external middleware.

These capabilities are valuable in theory, but what do they look like in practice? Let’s look at how one enterprise team transformed their testing process with the connector.

Real-World Success Story

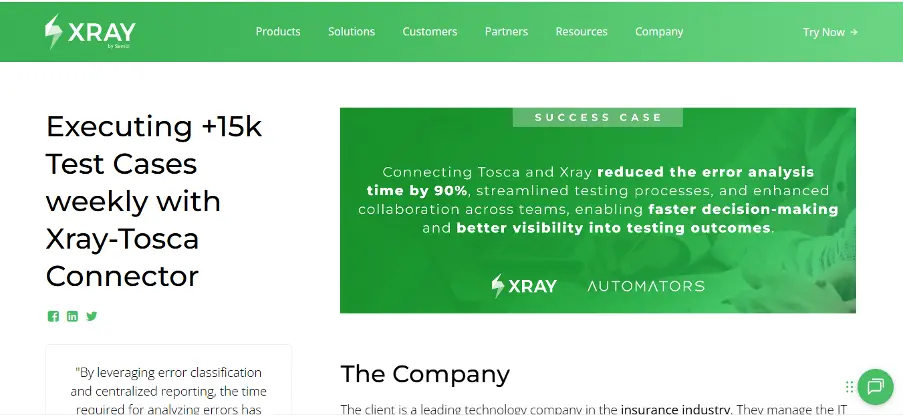

One of the strongest validations of the Tosca Xray integration comes from a leading insurance technology company in Central and Eastern Europe. The QA team faced the classic challenge: Tosca was running thousands of automated tests every week, but results had to be merged manually into Xray reports. This slowed down releases and limited visibility for business stakeholders.

After rolling out the connector, the results were clear:

- 15,000 automated tests executed weekly were seamlessly integrated into Xray.

- 50,000 test cases unified in one system, creating a single source of truth.

- Error analysis time reduced by 90%, thanks to AI-driven error classification.

- Reports available 2–3 days earlier than before, giving faster feedback cycles.

- 100+ business users gained access to Tosca results directly through Xray dashboards.

For this team, the connector transformed a fragmented workflow into an end-to-end test management process. Instead of waiting days for manual reports, stakeholders could make informed decisions every Friday with live Jira dashboards.

Frequently Asked Questions

Can Tosca integrate with Xray in Jira?

Yes. Tosca can be integrated with Xray through different methods, but the fastest and most reliable approach is using a dedicated connector.

Does the connector work with both Xray Cloud and Server/Data Center?

Yes. The Automators AI Tosca–Xray Connector supports all versions of Tosca and Xray, so it works across Cloud and Server/DC deployments.

Will screenshots and execution evidence be available in Xray?

Yes. When a test runs in Tosca, the connector automatically transfers results, logs, and screenshots into Xray Test Executions, ensuring full traceability.

How does the connector handle tool updates?

Unlike custom scripts, the connector is maintained for compatibility with Tosca and Xray updates. This prevents integration breakage and reduces long-term maintenance costs.

Final Words

When QA teams rely on both Tricentis Tosca and Xray for Jira, integration is the key to true end-to-end visibility. Without it, results stay siloed, reporting slows down, and stakeholders lose confidence in the process.

The Automators AI Tosca–Xray Connector solves this by synchronizing test cases and results in both directions, transferring full execution evidence, and even using AI to reduce error triage time by up to 90%. The result is unified reporting, faster feedback cycles, and stronger collaboration across QA and business teams.

If you want to see how it works in practice, explore the Tosca–Xray Connector product page or book a short consultation with our team. We’ll walk you through the setup and show you how to eliminate reporting delays and data silos for good.